| Wind Watch is a registered educational charity, founded in 2005. |

In depth: High-wire act is taking wind power to new scales

Credit: Darius Snieckus | Recharge | www.rechargenews.com 23 May 2012 ~~

Translate: FROM English | TO English

Translate: FROM English | TO English

Danish turbine developer Edmond Muller is in the early stages of detailing a potentially revolutionary “multi-deca-megawatt” concept that would dwarf the largest designs for the coming generation of European wind farms.

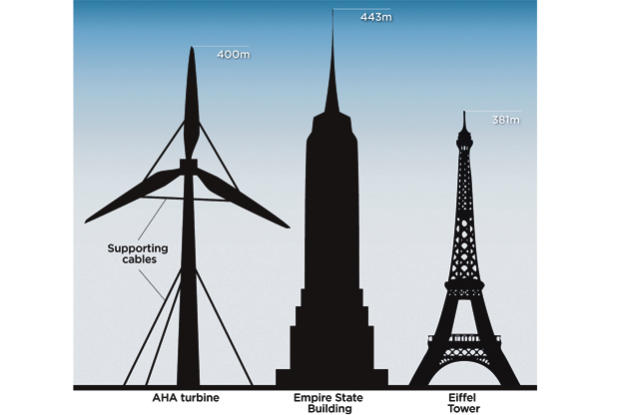

Featuring a three-bladed, 300-metre-diameter rotor atop a 250-metre-tall tower to create a swept area of 70,685 square metres, the 30MW Adaptable Hybrid Aerogenerator (AHA) is testimony to bigger being better.

A turbine of this unprecedented size would also have to deal with titanic forces and loads. To handle these, Muller has taken inspiration from many sources – even revisiting groundbreaking designs such as Johannes Juul’s iconic turbine erected at Vester Egesborg, Denmark, in the 1950s, which used a system of stay cables to support the tower.

“The AHA is a unique XXXL design that is intended to improve annual energy yield with minimal land use. [It is] an economically viable and technically feasible concept that has manageable logistics and a high sustainability score, and should be able to get a share of conventional markets, while opening up other, currently untapped, global markets,” says Muller.

“Many of the most ground-breaking early designs for wind turbines are now treated as caricatures, but they have a great deal to offer if the technology is modernised. The Juul test turbine, for example, used guy wires – something also advocated by researchers at Risø DTU [at the Technical University of Denmark] in the 1980s – but prejudices and lack of knowledge about the all-round advantages of technologies like these means much of the industry has not taken seriously things that could make very large wind turbines much more sustainable.”

Guy wires are one of many key elements in the AHA concept: the gravity loading on the turbine’s ultra-long blades will be offset by a novel rotor design with wires fixed at a midway point on each, while the tower is held in place with high-tensile cables similar to those used on suspension bridges.

The all-steel tower itself is iconoclastic. Designed with an aerofoil-like cross-section, it will pivot on its foundation, yawing with the prevailing wind. This significantly reduces loads on the structure and greatly diminishes the “tower shadow” as the blade sweeps past the tower – halving the machine’s infrasound noise and boosting output by smoothing periodic production losses caused by harmonics and sudden loading.

This slimline design would mean less – and lower-grade —steel for fabrication, reducing the weight of the structure “by half compared to a like-sized monopile turbine” and “dramatically” cutting the cost of manufacture. The tower would be fabricated in modules for assembly at site.

“The blades, the tower… everything would be sectioned in such a way as to make it transportable for onshore installations,” says Muller.

Due to intellectual property regulations, Muller is limited in what he can say about the rotor and nacelle componentry.

The blades, he notes, are likely to be made of a carbon-reinforced fibreglass composite and use trailing-edge flaps to lessen wind loads and boost energy capture, while the drivetrain “could use one of many new, innovative transmission designs we are seeing emerging”, with the safe money on a medium-speed hybrid gearbox with permanent-magnet generator.

The AHA claims many advantages over its smaller mega-scale brethren, not least that it will harvest wind at heights above the reach of conventional turbines in the atmospheric boundary layer – where velocities are “significantly higher” and the wind flow has less sheer and turbulence.

“Because the AHA is capturing wind at such altitudes, you get much more energy, so you could get 100% of the velocity as input,” says Muller. “Optimally equipped and properly laid out, an AHA site would be characterised by incredibly high yields.

“This would mean that the AHA would open up many areas today believed to be uneconomic – you would not need the most expensive and/or richest resource sites to make a development economically viable.”

Muller’s calculations suggest a 40% potential annual increase in MWh per square kilometre compared to existing wind farms’ output.

“One of the real advantages with this size of turbine is that you can build a wind farm with only one row,” states Muller. “And if you want to go bigger still, then you can arrange the turbine with inter-row distances of 10-50km to hugely improve the down-wind recovery.”

The vast tracts of space between AHAs would also drive up energy capture by eliminating wind-wake issues.

The tower could also be viable for installation offshore in water depths of up to 100 metres, reckons Muller. “A slightly adapted system would make it possible to install the AHA in deep water because you don’t have the weight or profile problems of a monopile tower, and you could pivot the tower to let large waves pass.

“Construction of the AHA for offshore would, of course, be much more straightforward because everything could be assembled quayside and then floated out for installation.”

Muller is computer-modelling the AHA in order to fine-tune its detailed engineering.

Longer-term, he hopes to build a first unit using a conventional 150-metre-diameter rotor to check his tower concept, followed by a 200-metre-diameter “true AHA” version so he can test the integrated design.

This article is the work of the source indicated. Any opinions expressed in it are not necessarily those of National Wind Watch.

The copyright of this article resides with the author or publisher indicated. As part of its noncommercial educational effort to present the environmental, social, scientific, and economic issues of large-scale wind power development to a global audience seeking such information, National Wind Watch endeavors to observe “fair use” as provided for in section 107 of U.S. Copyright Law and similar “fair dealing” provisions of the copyright laws of other nations. Send requests to excerpt, general inquiries, and comments via e-mail.

| Wind Watch relies entirely on User Funding |

(via Stripe) |

(via Paypal) |

Share: